Service Breakdown

Maintenance & Services: We offer complete maintenance servicing of CNC milling and turning machines that meets or exceeds manufacturers’ specifications. Whether we are needed for a maintenance consultation, single-service maintenance request or full-service scheduled maintenance plan/subscription, we ensure maximum machine availability and operation. Our maintenance services include: schedule-based plans, drive optimization, geometry verification, adjustments and calibration and full equipment reconditioning (remote facilities and on-site).

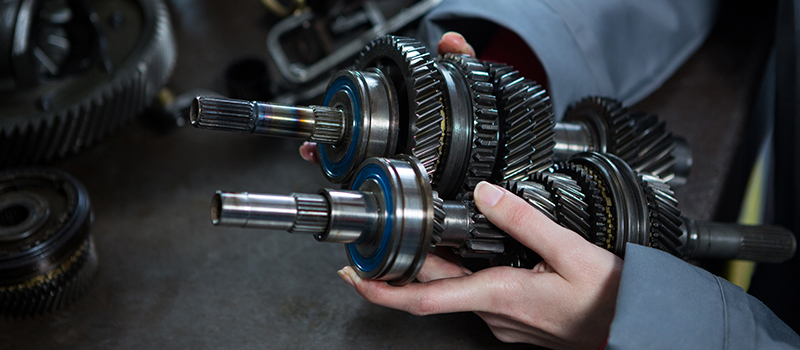

Repair: All CNC Service provider knows that there comes a time when parts and machines eventually fail. Our extensive experience in maintenance and service has offered us the same caliber of expertise in repair. Our repairs include: mechanical and electronic components, spindle repair, replacement of OEM parts, pump repair, scale repair, hard drive repair/replacement and realignments. As with our maintenance and servicing, all Parts are completely warrantied.

Machine Installation & Commissioning

We offers “up-to-date,” factory-trained technicians who will install your machines to full manufacturers’ specifications.

We guarantee that all installations will meet specific factory protocols and guidelines.

We offer both standardized and customized installations, based on the needs of your facility or workflow schematics.

Once installation is complete, our trained technicians will re-assess all protocols to ensure the accuracy of the installation, thus guaranteeing the operations and efficiency of your CNC machine.

Annual Preventive Maintenance Contract

Most machine shops overlook routine care of one of their greatest investments … their machines!

Our service technicians keeping your downtime to a minimum and quickly locate any necessary replacement parts.

- During scheduled service calls, our technicians will assess potential machine failures, preventing further unexpected downtime.

- Machines older than one year need Preventative Maintenance on a quarterly, bi-annual or annual basis.

- Most costly repairs to machine tools are as a result of lack of lubrication and/or undetected minor problems that could be eliminated with routine Preventative Maintenance.

- A Preventative Maintenance Program offers more than just fluid changes, your machine will undergo an in-depth inspection process, upon completion you will be provided with a detailed report.

- Regular Preventive Maintenance can be performed during non-operational hours, so there is no loss of valuable production time.

Retrofit

Machine retrofits are possible in various levels. A retrofit can be as basic as replacing old existing or new optional accessories or major machine parts recommended (including: axes motors, spindle and drives with new AC digital servo, software & hardware technology) or clamping / holding, feeding , tooling etc.

A comprehensive retrofit for example would include an all new machine electrical system such as CNC control, AC digital servo motors and drives, complete machine wiring, linear and rotary encoders for closed loop positioning feedback, new operator pendent, and new electrical cabinet etc.

Our FANUC CNC retrofits are not complete until a full set of documentation is delivered to the customer. Without proper documentation, repair of a simple problem can be a nightmare.